FMD #44

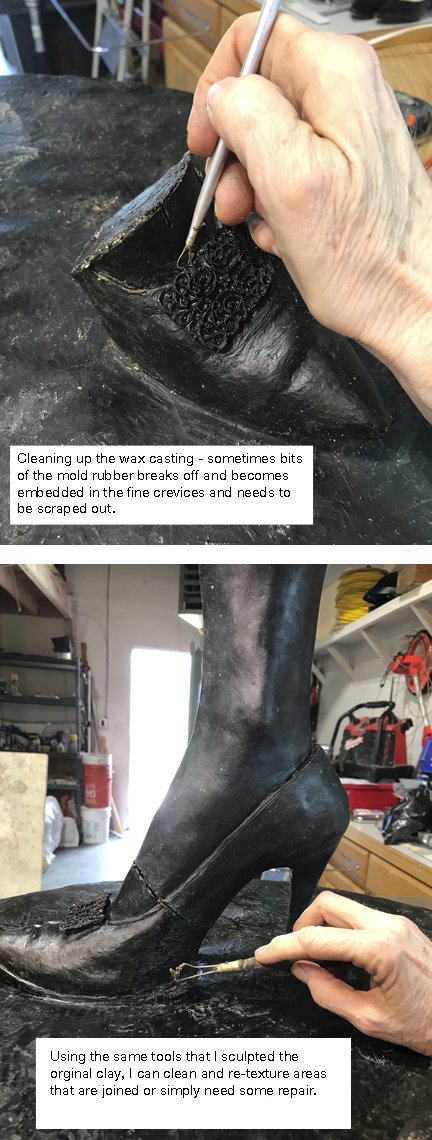

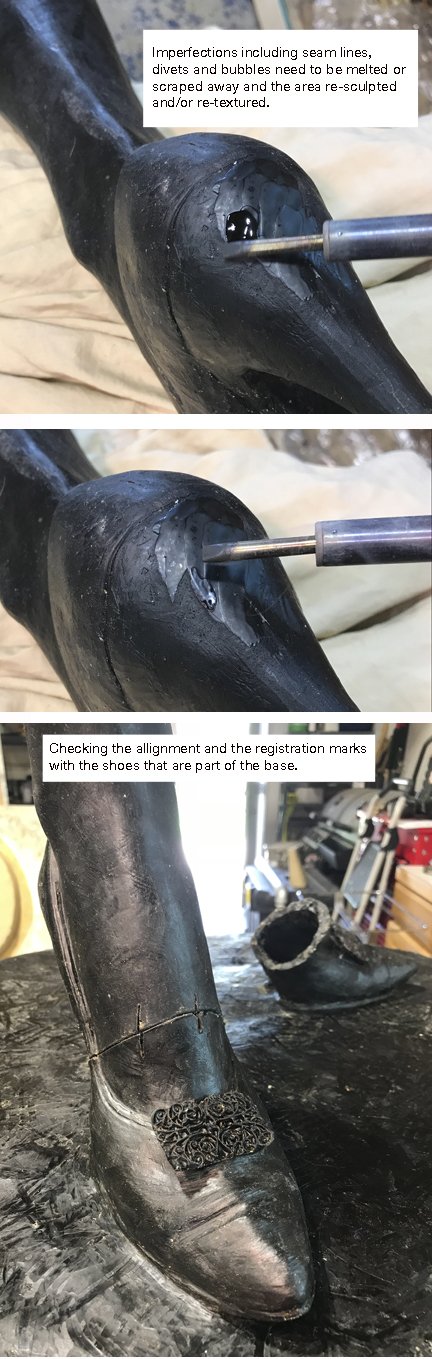

Even with the very best molds and wax pours, there will still be work to do. In the case where there were any supports or areas that were cut off from the main sculpture, those areas will now have a plug of wax that will need to be removed and the area plugged and retooled and/or sculpted. Additionally there will be seams from where the two halves of the mold joined and sometimes ‘flashing’ which is thin areas of wax that may seep out between the mold halves that will need to be removed. When making a new plug that is large, I draw a template outline of the hole, place that under glass and form a dam using ceramic clay, the pour molten wax into the dam to cool. The plug needs to be the same thickness as the rest of the wax: 3/16” to 1/4” thick.

Once the new wax plug is firmly melted into the old wax it is allowed to cool. Then time will be spent in blending it into the rest of the sculpture and putting in the texture as needed.

Where the plugs to be removed are larger - such as in the openings of the legs, torso and bust, it is wise to leave some support so the openings do on become distorted. These wax supports will be removed prior to making the shell for casting in bronze.