FMD #50

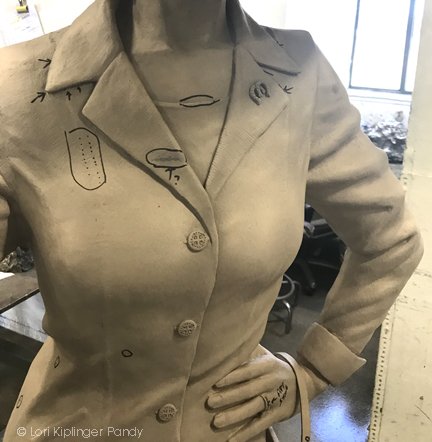

The next step after the initial welding is to sandblast the entire bronze surface. This makes the bronze easier to look at as it is uniform and removes all the shiny spots and rainbows that occur when welding and chasing the bronze. Now that the surface is easier to see it is much easier to spot any areas that still need work. The artisans do an excellent job of checking over the metal and by the time I arrive to view the work it already has many circles and notations written across the surface.

The foundry has its own shorthand that makes it easy for the welders and chasers to make notations and mark areas that will be worked on in the metal and taking a marker, I add a few of my own notes to the mix.

The purse strap is welded into place but will continue to be nuanced. I have requested that it be straightened a bit more to give more ‘weight’ to the purse hanging from her wrist…

The center stone in the ring was a bit cut off in the casting process and a note was made to add additional metal to the ring…

Tight areas and corners are notorious for having little bubbles of wax or metal in the casting. The notations here are saying to remove the little bubbles from the corners of her smile and the eyes - the circles are calling attention to other minor surface imperfections that will be chased away.

No area is glossed over in this stage - small details such as the underside of leaves and edges of roses are all scrutinized and refined in the metal.

The foundry will continue with the metal chasing and once complete I’ll come back down for another metal inspection of the bronze to ensure it is all finished and ready for the next step, the patina.